Powerful & affordable CMS: predictive maintenance strategy

The crucial basis for that is the interpretation of all kinds of measurement data.

This include especially vibration and SCADA data.

it provides in a reliable way high-quality data on drive train vibrations and bearing temperatures.

Only by this data will you understand the condition of your assets!

| The innovative CMS is based on Internet of Things (IoT) | Monitoring services with a minimum of preliminary costs |

Flexible Cloud-based software platform |

Next generation Condition Monitoring hardware

Developed on the basis of many years of experience in Condition Monitoring and diagnostics, ecoCMS offers high value for your business and is proven to reduce operating and maintenance costs.

It also offers significant savings in downtime and repair costs.

|

Technologies for sensors and electronics of the 21st centuryEach and every aspect of our life is dominated by digital technology - why then use an outdated CMS based on expensive analog sensors and electronics? ecoCMS uses powerful mobile computing technology combined with low-cost 3D MEMS sensors and robust digital communication between the sensors and the ecoCMS unit. Low power consumption means there are no moving fans, which are known to cause poor reliability in the field. Robust and secure communication between ecoCMS and the monitoring center is a fundamental requirement for the daily interpretation of measurement data. Why install costly additional components for a router, including power supply, fuse and housing if there is another way? ecoCMS is also a leader in this field.

The router function incl. SIM card is already "build-in" and pre-configured at delivery. Thus, you save on costs for additional hardware and installation.

The multi-network SIM card automatically searches for the best mobile network at your site. |

Most advanced & powerful sensor technology3D-MEMS (SD) – Standard Duty With three-axis accelerometers (X/Y/Z), each with an embedded sensor to detect bearing temperature, ecoCMS provides 24 vibration signals and 8 temperature signals.

The 3D MEMS accelerometer is attached to the housing structure with a fast-curing epoxy - fast installation; no drilling or tapping required. The 3D MEMS (SD) with a sampling rate of 7,600 S/s is optimized for wind turbine retrofit applications. It is generally suitable for well protected environments. |

|

|

3D-MEMS (HD) – Heavy Duty Three-axis MEMS accelerometer with temperature output in rugged stainless steel housing with bolt mounting.

It is particularly suitable for harsh and unprotected applications. The sensor provides higher frequency, sampling at 25,600 S/s. It is optimized for an industrial environment with high metrological requirementsr The 3D-MEMS (HD) is available with bolt-on terminated cables in a variety of length options (5m, 7.5m, 10m, 20m, 40m) and is available with metric M6 and inch 1/4-28 UNF through bolts.

This provides enhanced flexibility for complicated installations or when changing gearboxes. |

Seamless integration with monitoring software & servicesfleetMONITOR is a unique hardware-independent software platform for condition monitoring and preventive maintenance.

ecoCMS data is analyzed via the fleetMONITOR web application. This provides dashboard views for high-level alarms and trends, through to detailed vibration analysis tools for the expert analyst. Whether you want to do the monitoring yourself or need monitoring services from analytics experts - 8.2 Monitoring can support you.

8.2 and ONYX InSight routinely monitor vibration and SCADA data from more than 20 GW of wind turbines worldwide from monitoring centers around the world with fleetMONITOR.a The fleetMONITOR connects data from different sources. The fleetMONITOR is multi-brand capable, i.e. besides the data of ecoCMS, the data of many third-party CMS can be integrated. This can be used for taking over the analysis service after the expiration of the warranty as well as for the condition determination before the expiration of the warranty.

In addition, inspection results from the fieldPRO software can be integrated into the analysis.

All information is presented in a clear dashboard and can be viewed by the monitoring engineer, the plant manager and the operator at any time - via laptop, tablet or cell phone. |

|

|

Ready to use Installation8.2 and ONYX InSight can manage all aspects of your CMS installation program - whether it's handled by your technicians, a preferred third-party vendor, or 8.2/ONYX InSight's experienced engineers.

From working with IT departments to installing Ethernet cables in the tower and commissioning CMS units, we cover it all. Security is always our top priority, and 8.2 and ONYX InSight's strict internal standards ensure that ecoCMS installations are performed to the highest levels of security and quality. Track record: 6000+ installed ecoCMS | 40.000 3D-MEMS-sensors | 20 GW monitored with fleetMONITOR

|

Case studies:Damange of main and planetary bearings

|

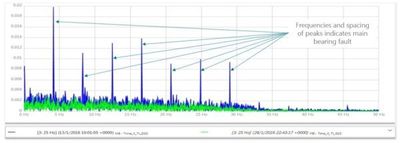

The vibration analysis shows a main bearing damage (blue) and a healthy main bearing of a neighboring turbine (green).

|

|

|

Result of boroscopy on main bearing

|

|

|

The vibration analysis of ecoCMS-data shows clear proof of damage on planetary bearing |

|

|

Damage on internal ring planetary bearing - proven by boroscopy! |